Overhead Refractory — Hidden Danger, Real Risk

Anchor failures and unstable refractory/coating in the preheater create one of the most critical shutdown hazards — a direct risk to people and plant.

How It Started

In 2012, following reviews of shutdown safety, Hucktek, working with Cemex and Heidelberg in the UK developed the first stainless steel refractory netting system for the preheater.

Since Then

Over 4,000 nets, 100 kiln lines, 32 countries.

Trusted by

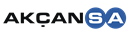

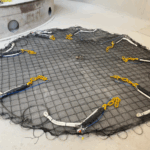

Catch Netting

Application

Close to refractory at cyclone roofs, riser ducts, calciner tops (goose necks), and kiln hoods.

Design

Multiple nets tailored to vessel geometry, providing maximum coverage. Installed from safe points outside the vessel; lightweight for handling.

Capacity

Proven to retain a refractory/coating block of 675 kg (1,000 × 1,000 × 250 mm) from a fall height of ~400 mm.

Installation

Nets are lightweight and installed from safe access points outside the vessel. Typical installation for a cyclone roof area is around 2 hours, depending on geometry, obstructions, and access.

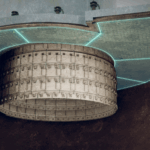

Impact Netting

Application

Installed across vertical ducts such as calciners, cyclone riser ducts, and kiln risers.

Design

Single heavy-duty nets are designed to cap off areas and safely capture greater fall heights and extreme loads. Supplied with an integrated dampening system to reduce impact forces.

Capacity

Proven to retain a refractory/coating block of 675 kg (1,000 × 1,000 × 250 mm) from a fall height of ~12.5 m.

Installation

Nets are heavier and installed from safe external access. Typical installation is around 2 hours per net, depending on geometry, obstructions, and access. Specialist tooling is available to help

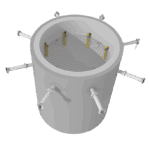

Custom Solutions

Beyond our core Catch and Impact systems, Hucktek designs site-specific safety netting such as dip tube retention. We work with plant teams to develop the right solution and ensure the safety of critical areas.